How to Troubleshoot and Maintain the Electrical System of a Classic Ford Bronco

Introduction

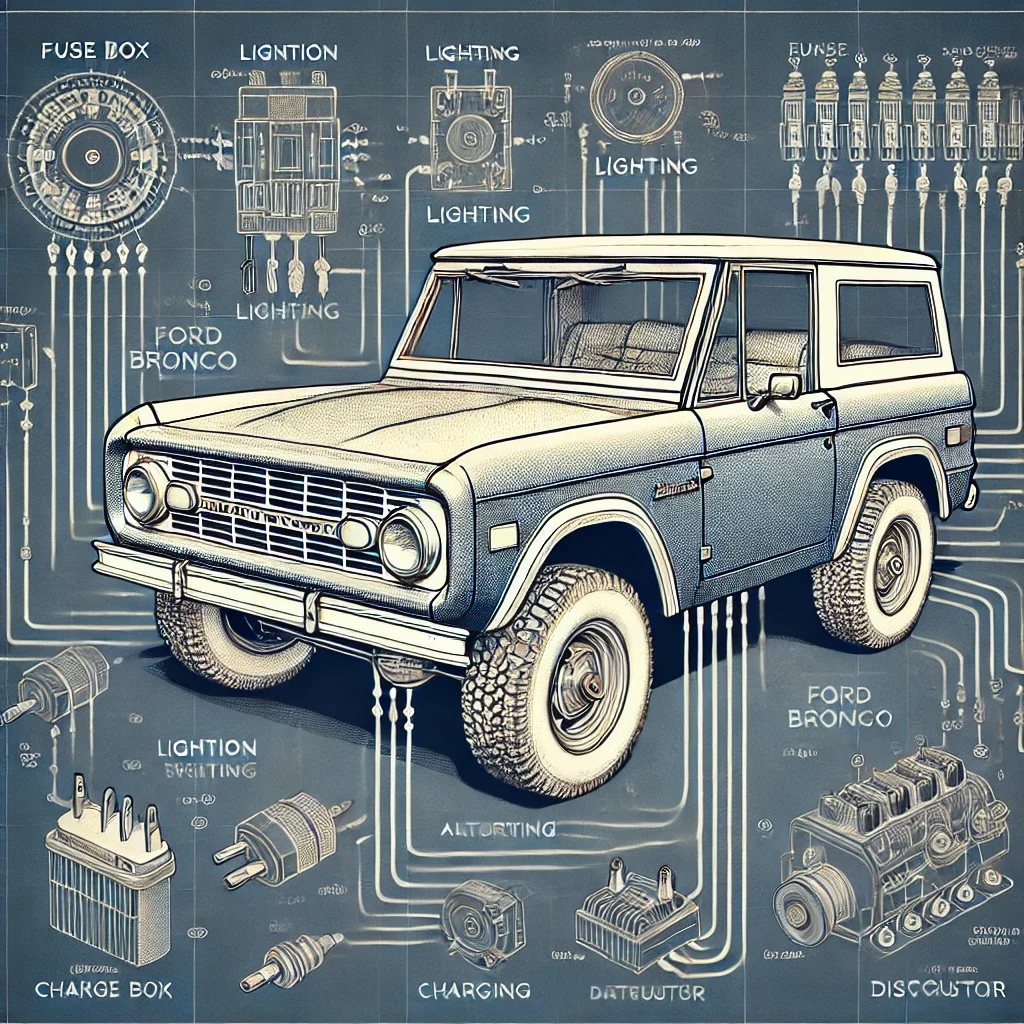

The electrical system in a classic Ford Bronco (1980-1990) powers critical components such as lights, ignition, and accessories. Ensuring that the electrical system is functioning properly is essential for safety and reliability. This article will guide you through diagnosing common electrical issues, performing regular maintenance, and understanding the key components of the system.

1. Components of the Electrical System

The electrical system in the Ford Bronco includes:

- Battery and Charging System:

- Battery.

- Alternator.

- Voltage Regulator.

- Ignition System:

- Distributor.

- Ignition Coil.

- Spark Plug Wires and Spark Plugs.

- Lighting System:

- Headlights, Taillights, and Turn Signals.

- Reverse and Brake Lights.

- Interior Lights.

- Accessories:

- Dashboard Instruments.

- Wipers, Radio, and Heater/AC Controls.

- Fuses and Relays:

- Fuse Box.

- Relays for various circuits.

2. Common Electrical Problems and Their Solutions

A. Dead Battery

- Cause: Old or damaged battery, parasitic drain, or a failing alternator.

- Solution:

- Test the battery with a multimeter; replace if voltage is below 12.4V.

- Check for parasitic drain by disconnecting the battery and using an ammeter.

- Inspect and replace the alternator if it’s not charging the battery (should output 13.8-14.5V when running).

B. Dim or Non-Working Lights

- Cause: Faulty bulbs, poor ground connection, or corroded wiring.

- Solution:

- Replace damaged bulbs (e.g., HL6054 for headlights).

- Clean ground connections and ensure proper contact.

- Inspect wiring for corrosion or breaks and repair as needed.

C. Ignition Issues

- Cause: Faulty distributor, ignition coil, or spark plug wires.

- Solution:

- Replace the distributor cap and rotor if worn (Part: DR440).

- Test the ignition coil with a multimeter and replace if faulty.

- Inspect and replace damaged spark plug wires.

D. Blown Fuses

- Cause: Short circuit or overloaded circuit.

- Solution:

- Check the fuse box and replace blown fuses (e.g., 15A for lighting circuits).

- Identify and repair the source of the short circuit.

3. Routine Electrical Maintenance

A. Battery Maintenance

- Clean battery terminals to prevent corrosion.

- Ensure the battery is securely mounted to avoid vibration damage.

- Test the battery voltage every 6 months.

B. Wiring Inspection

- Inspect wiring harnesses for frays, breaks, or loose connections.

- Use electrical tape or heat shrink tubing to repair damaged insulation.

C. Alternator Check

- Test the alternator output with a multimeter (should be between 13.8-14.5V).

- Replace the alternator belt if it shows signs of wear or cracking.

D. Fuse Box Cleaning

- Remove dust and debris from the fuse box.

- Ensure all fuses and relays are securely seated.

E. Spark Plug and Wire Maintenance

- Replace spark plugs every 15,000 miles (24,000 km) or as needed.

- Inspect spark plug wires for cracks or burns and replace them with WC327.

4. Tools for Electrical Repairs

- Multimeter: For testing voltage, resistance, and continuity.

- Test Light: For identifying live circuits.

- Wire Strippers and Crimpers: For repairing wiring.

- Heat Shrink Tubing and Electrical Tape: For insulating repairs.

- Fuse Puller: For safely removing and replacing fuses.

5. Troubleshooting Tips

- No Power or Intermittent Power:

- Check the battery connections for tightness and cleanliness.

- Inspect the main ground strap for proper contact.

- Headlights Flickering:

- Test the headlight relay and replace if necessary.

- Inspect the alternator for voltage irregularities.

- Dashboard Instruments Not Working:

- Check the instrument panel fuse.

- Inspect the wiring behind the dashboard for loose connections.

- Blown Fuse Keeps Repeating:

- Identify the faulty circuit by tracing the wiring and checking connected components.

- Repair any damaged wires or replace defective components.

6. Recommended Replacement Parts

Here are common replacement parts for the electrical system of the Ford Bronco:

- Battery: Part Number: BAT9501.

- Alternator (95A): Part Number: ALT9502.

- Distributor Cap and Rotor: Part Number: DR440.

- Ignition Coil: Part Number: IC302.

- Headlight Bulbs (Halogen): Part Number: HL6054.

- Fuses and Relays: Part Number: FR1124.

- Spark Plug Wires: Part Number: WC327.

7. Upgrades for the Electrical System

If you’re restoring a Ford Bronco, consider upgrading some components for improved reliability and performance:

- LED Headlights: Brighter and more energy-efficient.

- High-Output Alternator: Supports additional accessories like winches or sound systems.

- Modern Fuse Box: Simplifies future electrical repairs and upgrades.

Conclusion

Maintaining the electrical system in a classic Ford Bronco ensures its reliability and functionality. By diagnosing problems early, performing routine maintenance, and upgrading key components, you can keep your Bronco running smoothly for years to come. Whether it’s off-road or on the street, a well-maintained electrical system powers every part of your classic vehicle.