Understanding Oil Pump Malfunctions: Causes and Solutions for Engine Lubrication Issues

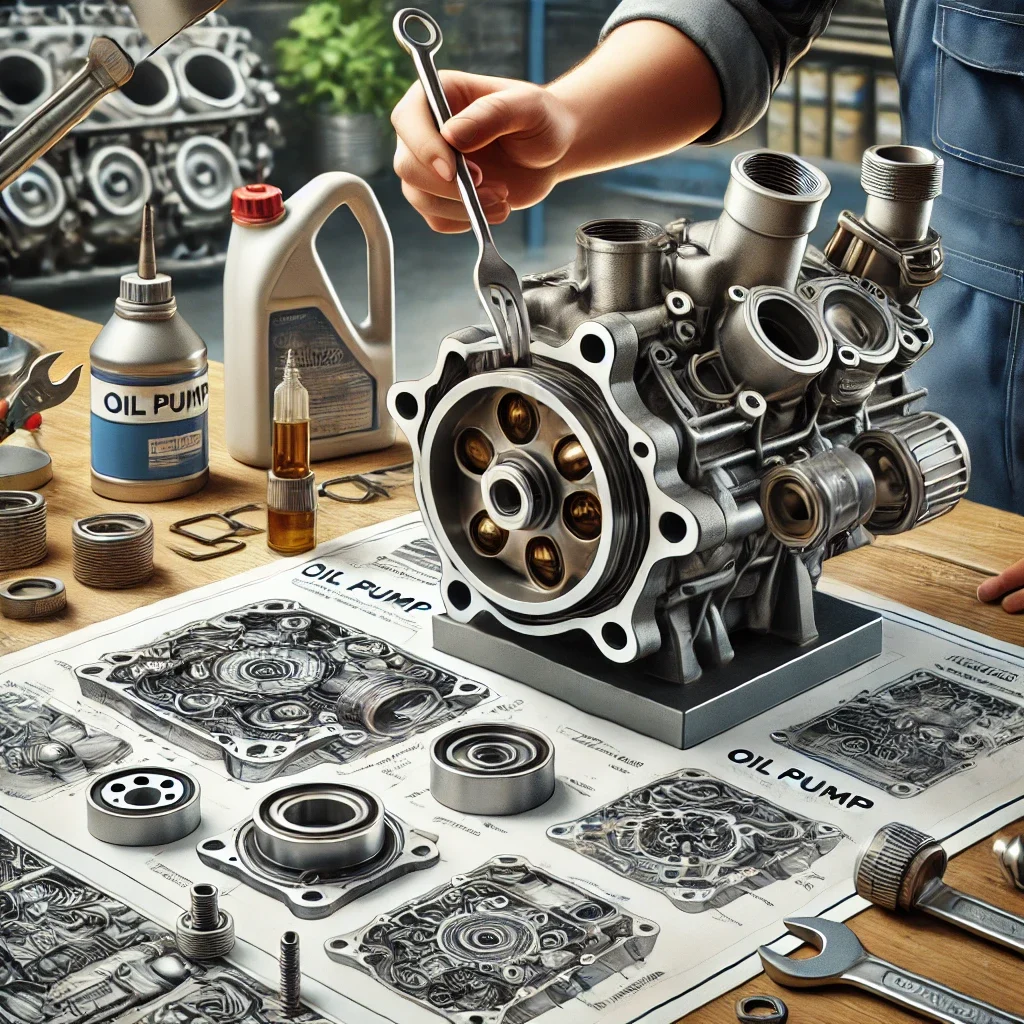

Ensuring the smooth operation of an engine hinges significantly on effective lubrication, primarily facilitated by the oil pump. An oil pump, designed to distribute engine oil throughout the internal components, plays a crucial role in preventing wear and tear, overheating, and potential engine failure. Understanding the common malfunctions of an oil pump, their causes, and potential solutions can empower vehicle owners and mechanics to maintain optimal engine health.

Common Causes of Oil Pump Malfunctions

- Wear and Tear on the Drive Shaft: One of the primary causes of oil pump failure is excessive wear on the drive shaft. If the wear surfaces of the drive shaft are more than just shiny, it is crucial to replace it. A worn drive shaft can lead to instant oil-pressure loss, severely damaging engine components.

- Debris Circulation: Oil pump damage often arises from metal or dirt particles that pass through the pump. These particles can enter the oil system due to other components malfunctioning—for example, a chewed-up cam lobe or a clogged oil filter. When oil bypasses a blocked filter, it can circulate debris through the pump, creating significant scoring and damage to the oil-pump rotors and housing.

- External Damage: Impact from external sources can also cause damage. A sudden impact or jolt could misalign the oil pump or damage its housing, leading to inefficient oil circulation.

Identifying Oil Pump Malfunctions

To expertly diagnose oil pump issues, mechanics can perform specific inspections:

- Visual Inspection: Look for signs of oil leakage around the pump. Any visible leaks can indicate internal malfunctions.

- Performance Testing: Immerse the pickup in clean solvent and turn the rotors. A successful test will result in solvent gushing from the pump’s pressure port after a few turns, indicating functional rotors and clearances.

- Clearance Measurement: Utilizing feeler gauges, measure the clearances between the rotor and the housing. Ensure that the maximum clearance does not exceed the recommended specifications—0.013 inches for outer rotors and 0.004 inches for rotor end-play. Excessive clearances can indicate wear.

Solutions for Oil Pump Malfunctions

- Regular Maintenance: One of the best preventative measures is regular oil changes and timely replacements of oil filters. Ensuring that the oil is clean can significantly reduce the chances of debris damaging the pump.

- Drive Shaft Replacement: If wear on the oil-pump drive shaft is observed, it is advisable not to practice false economy by reusing it. Replacing a worn drive shaft can prevent sudden oil pressure loss and further damage.

- Oil Filter Checks: Regular checks and replacements of the oil filter can prevent large dirt particles from circulating through the oil pump. A clogged filter can severely compromise lubrication.

- Pump Replacement: If severe scoring or damage to the rotors or pump housing is evident during inspection, replacing the oil pump may be necessary. This action will ensure that oil flows correctly to lubricate engine components satisfactorily.

Conclusion

Understanding the intricate workings of an oil pump, and being aware of the potential causes of malfunction, can go a long way towards ensuring your engine’s longevity and performance. By performing regular inspections and maintenance, and being proactive in addressing any signs of trouble, vehicle owners can avoid costly repairs and ensure their engine functions smoothly for years to come. Always consult a qualified mechanic if you suspect issues with your oil pump to seek the most precise diagnosis and effective solutions.